Torque-as-a-service

by kongsberg maritime

Get precise torque measurements as a service – limited up-front investment costs and no servicing costs.

Why choose this solution

LIMITED INVESTMENT COST

Get access to accurate and crucial performance data. Without making huge up-front investments.

NO SERVICE COSTS

Full product warranty throughout the lease period.

EASY ACCESS TO PERFORMANCE DATA

View performance data on the desired platform onboard or on shore.

SEE IT IN ACTION

Features

MORE THAN JUST SHAFT POWER

MetaPower Quad is based on a patented design capable of more than just shaft power. Two slotted wheels are installed with some distance between them on the shaft. Laser sensors individually read the wheels relative position thus reading the actual twist of the shaft.

Industry leading high-res processing of torque and power data computed for every 1° of shaft revolution. Essential data are provided via TCP/IP for fast & lag-free communication. Also provides pre-processed data sets for in-depth torsion analysis and loads of other possibilities.

A COMPHREHENSIVE MEASUREMENT TOOL

Obtaining a long-term, precise measurement of torque transferred by a solid piece of shaft-steel, is one of the most challenging measurements on a ship. This measurement is used for many KPI’s when it comes to engine and vessel performance. Having a precise measurement is crucial for the validity for making the correct decisions. Kongsberg has developed it’s patented torquemeter over many years, with strong emphasize on long-term correct measurement, ease of use, and additional functions.

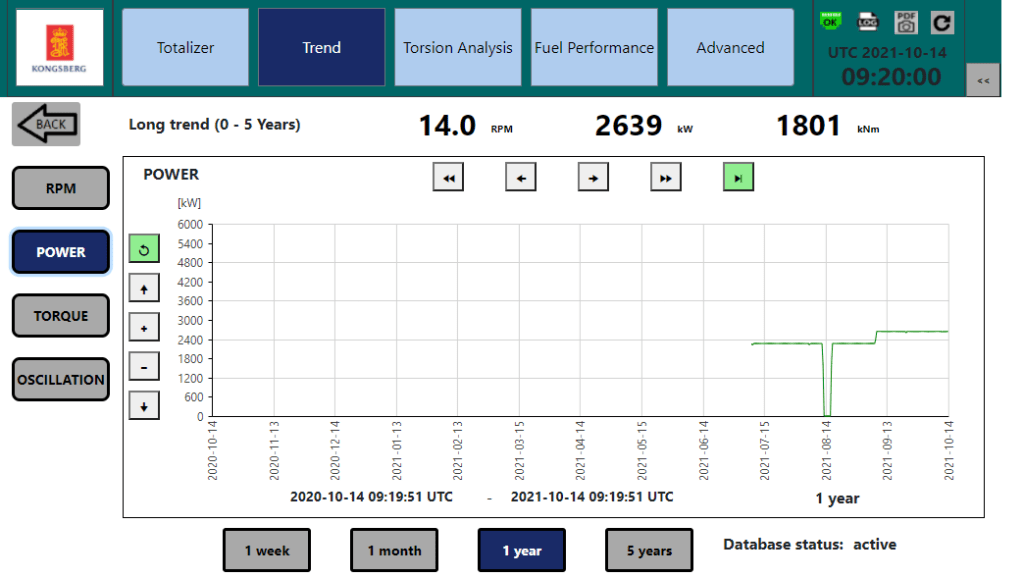

OBTAINING DATA - KEEPING DATA

ISO 19030-2:2016(E) defines delivered power as one of two primary parameters for measuring changes in hull and propeller performance. The standard also specifies minimum data acquisition rates, which the data shall be recorded with. For engine power this is 0.07Hz, or once every 15s.

MetaPower Quad has built in capacity to store such data for minimum 10 years. View the performance data in any relevant time perspective. The system is of course ready to share data. Connect to it with industry standard Modbus (TCP or RS-485), use the HTTP web interface or access the history database remotely with an SQL program.

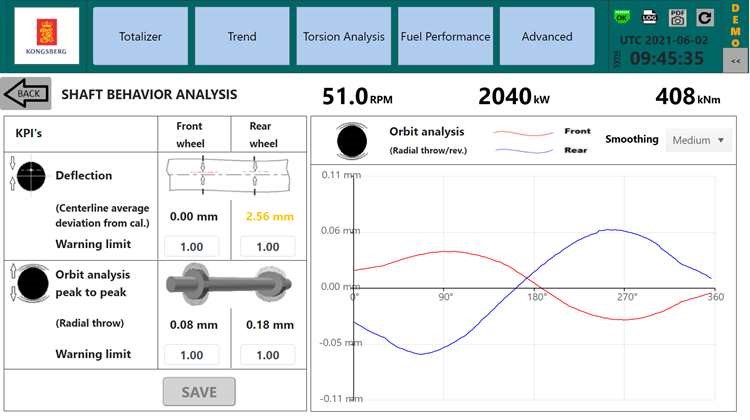

SHAFT DEFLECTION (BENDING) AND ECCENTRICITY DETECTION

Using advanced algorithms, the quadrature arrayed sensing solution can detect deflection in the shaft, caused by bending forces and poor shaft alignment. The user will be alerted if the shaft is excessively bending, or exercise eccentric movements throughout the revolution. The warning limits are adjustable to accommodate most installations.

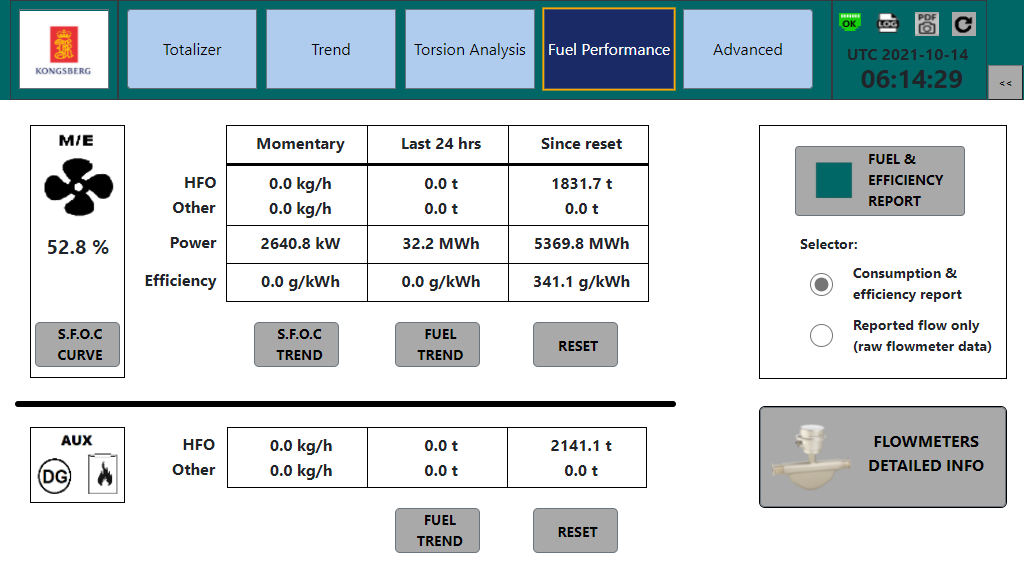

FUEL PERFORMANCE

MetaPower Quad is capable of interfacing up to 8 fuel flow meters via Modbus. Configuration, simulation and long-term logging is part of the scope, in addition to the calculation of specific fuel consumption(SFOC).

NMEA interface to ship navigation data makes MetaPower Quad a complete and single source for vessel performance data, compact, installation friendly and cost efficient. Fuel and voyage data can be stored in the system up to 10 years. Use the report function or access the SQL data channel. The internal logging storage capacity is ~25 Gb, enough for most users.

NB: KONGSBERG recommend Coriolis Mass Flow Meters for highest possible accuracy.

FLEXIBLE COUPLING MONITORING

Most medium speed engines are fitted with flexible couplings. The coupling plays a vital role in protecting the engine from torsional vibrations etc. initiated by the shaft line and propeller. MetaPower Quad can, with added sensors monitor the integrity of the coupling, present developing deterioration by visualizing the long-term trend and give alarm at critical levels.

The coupling may become too loose, but equally important is hardening of the rubber which cause transfer of unwanted torsional vibrations to the propulsion line. MetaPower Quad detects both.

DATA HANDLING AND ACCESS

Data is logged and stored within the system for a minimum of 10 years. Access to data is made through multiple options:

Seamless interface to KONGSBERG cloud solution KOGNIFAI and applications running on that platform on board and on shore.

On-ship access via ship network and http protocol. Any PC with a web browser, or a mobile phone can be used.

Automatic distribution of reports via email. The HSIO in Metapower Quad can be set up to send truncated data and reports by e-mail to any mail address on shore via the ship mail server. This requires the onboard IT network to be set up accordingly. (Not part of KM scope)

OptionS

Clutch Slip Detection: By interfacing engine flywheel sensor (ME RPM sensor) to the shaft cabinet, the system will compare revolution speed between shaft and engine. Provided with the gear ratio, the system will alert immediately if the clutch is slipping.

Crank Shaft Monitoring: By interfacing encoder in front of engine to shaft cabinet, crank shaft monitoring is possible. Comparing encoder signal to front shaft code-wheel signal can provide insight on torsion and oscillations, isolated to the Main Engine crankshaft.

INDEPENDENT VALIDATION

Reference is made to DNV Report No: 2021-0094 rev01, which presents the results of the verification measurements. The measurements demonstrated that the MetaPower Quad system can achieve the intended accuracy required for power measurements in ISO 15016:2015(E) for measurements on board a ship undergoing trials, as verified on two separate shafts on board vessel Skandi Vega (IMO no: 9435715) on 30.11.2020.

Full report available from DNV or KONGSBERG.

Customer voices

Example text: This product has had a significant impact in improving our bottom line. By using this product we have managed to save 20% of fuel and improved our vessel operations significantly.

Example Customer

Example Customer

Additional Information

Delivered by:

ABB Turbocharging is at the helm of the global industry in the manufacture and maintenance of turbochargers for 500 kW to 80+ MW diesel and gas engines. Our innovative leading-edge technology enables our customers to increase their performance; producing lower emissions, and improving fuel consumption even in the toughest environments. Approximately 200,000 ABB turbochargers are in operation across the globe on ships, power stations, gen-sets, diesel locomotives and large, off-highway vehicles. We have over 100 Service Stations in more than 50 countries globally and a wide service portfolio that guarantees Original Parts and Original Service anytime, anywhere.